Your Cart is Empty

True Kit are sending boats to all parts of the world on a daily basis - orders are dispatched in 1-3 business days

True Kit are sending boats to all parts of the world on a daily basis - orders are dispatched in 1-3 business days

BOATS

Our unique lightweight landing craft range

Our ultra lightweight inflatable tender range

Our most portable, long and sleek, inflatable fishing kayak

Link to your collections, sales and even external links

Our unique lightweight landing craft range

DISCOVERYS

Our ultra lightweight inflatable tender range

NAVIGATORS

Our most portable, long and sleek, inflatable fishing kayak

TACTICIAN

Link to your collections, sales and even external links

THE STOWAWAY

PACKAGES

Our carefully selected accessories to match with the Discovery

Useful accessories are bundled in with our Navigator tender

Our carefully selected accessories to match with the Discovery

READY FOR DISCOVERY PACKAGE

Useful accessories are bundled in with our Navigator tender

CAPTAINS PACKAGE

ACCESSORIES

HOW TO: Repair your Inflatable Boat

October 16, 2021 3 min read

Do it once, do it right!

There are many advantages to owning an inflatable boat: they are very portable, they are lightweight, incredibly stable, super safe and perfect for many applications like fishing, diving, exploring or use as a tender for a larger boat. However if you are using the boats hard there is always a chance you are going to need to do a repair at some stage.

Repairs done properly should last the lifetime of the boat, however repairs that aren't done correctly are likely to come apart the next time you use the boat. In this article we go over how we do repairs to True Kit inflatable boats in our workshop.

It is worth noting that our True Kit boats are made from a fabric called Valmex® made by German company Mehler. Valmex is a premium quality pvc-coated fabric. The first thing you need to determine is what your inflatable boat is made of and match how you repair the boat to that fabric.

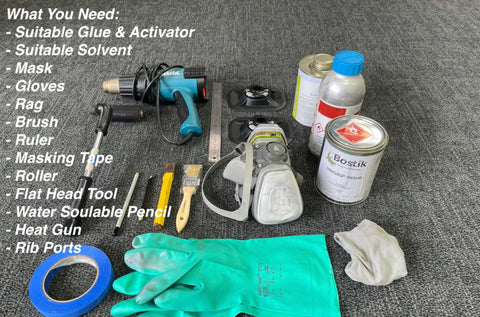

As with most jobs, the preparation is very important. First you need to assemble all the right equipment:

This list might include:

- Suitable 2-pot glue (the second part being the activator/crosslinker) - Bostik Unigrip 999HR with Desmodur RFE used at 10%

- Suitable solvent (MEK in our case)

- Mask

- Gloves

- Masking Tape

- Rag

- Brush

- Ruler

- Knife

- Roller or other tool to work the two surfaces together

- Water soluble pencil

- Heat Gun

- Repair fabric

Step 1

Identify the area that needs a repair. This may sound simple but often a hole can be very small and not easy to find. We use a spray bottle with a mixture of water and dishwashing liquid. Always spray a much larger area than where you think the hole might be as often there will be a second hole you haven't spotted.

Note very small repairs can be done with the boat inflated (also the way you would follow these instructions to add an extra fitting onto a boat), however if the repair is large you will want to do it with the boat in a DEFLATED state. This will stop back-pressure pushing the patch off.

Step 2

Cut out some suitable sized patches using the same fabric that your boat is made from. As a rule of thumb try to have 25mm or 1 inch of patch cover outside the area needing repair.

Step 3

Use the water soluble pencil to trace around the patch. This gives you the exact area that needs to be masked off for glue application.

Step 4

Using the masking tape accurately mask around the pencil outline

Step 5

Clean both surfaces using the rag and the MEK solvent. This cleans and primes the surface for the glue

Step 6

Thoroughly mix the 2 parts of glue together according to the instructions that come with the glue you have. With the products that we use, we mix together at a ratio of 10% activator. Allow a few minutes for the glue and activator to combine.

Step 7

Take the small paint brush and cut the bristles to around half length. This makes the brush bristles stiffer and allows you to apply the glue more evenly over the surfaces.

Step 8

Use the cut down paint brush to apply an even layer of the glue to both surfaces. Some glue products call for more than one application of the glue. In all cases, with a contact adhesive you want to leave the glue to tack off. This is typically around 15 minutes but depends on the temperature. To check the surface is not sticky, you never want to use your finger tips. Instead you can use the knuckle side of your fingers or better still and gloved hand.

Step 9

As our glues are heat activated, we now use the heat gun (a hair dryer can also be used) to warm both surfaces up. Only a a modest heat is applied, something that your hand could handle. This heat reactivates the glue and makes them ready to bond together.

Step 10

Remove the masking tape and carefully place the patch onto the marked area on the boat. Then use the roller or other hard tool to apply pressure to the patch. This is an important step to amalgamate the two surfaces of glue together

Step 11

Allow 48 hours before pumping the boat up to full pressure. You can retest the boat using the soapy water again. Enjoy using your boat again!

Note: this step by step instructions is what we at True Kit use for our type of boats. These steps may not apply if you have a different brand of boat.